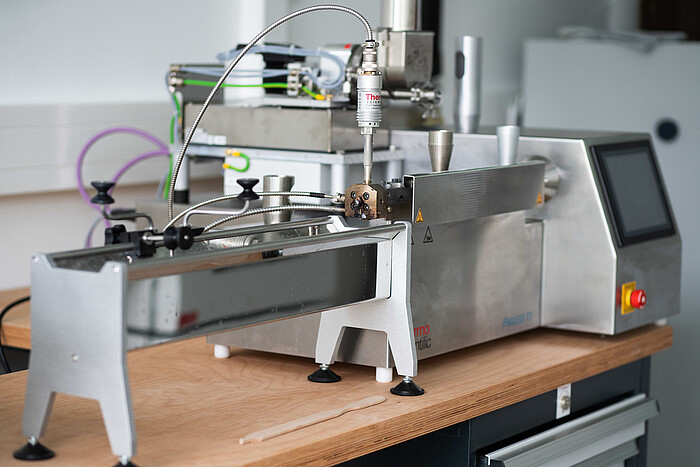

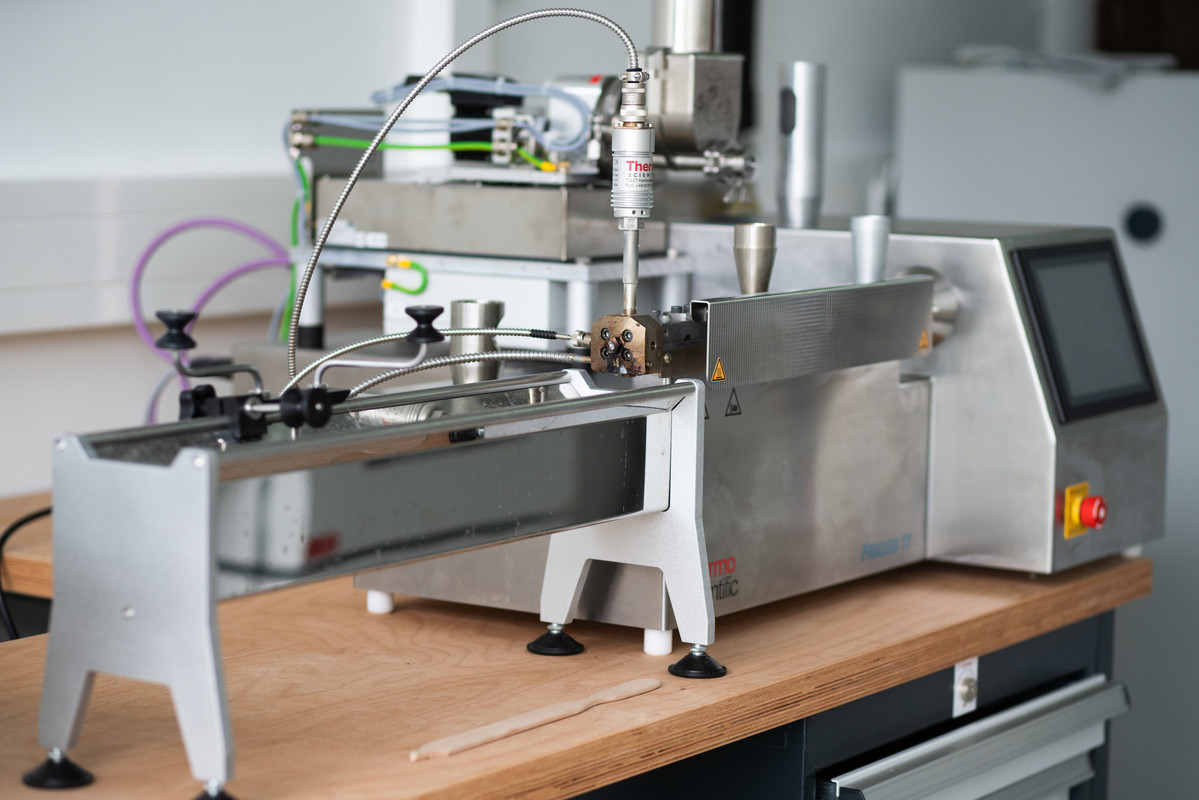

Lab-Extruder

©

Nico Niemeyer

©

Nico Niemeyer

Manufacturer: ThermoFisher Scientific

Short description: The modular design of the co-rotating twin-screw extruder allows thermoplastics to be melted, degassed, reinforced, filled, colored, functionalized with various additives, concentrated, homogenized and compacted.

Processing media: Thermoplastic (bio) plastics / compounds (granules, powder, grist), blends and (bio-based) composite materials

Applications: Recipe development/process optimization in R&D for thermoplastic (bio)plastics/compounds (pellets, powder, regrind), blends and (bio-based) composites.

Special features: Minimum throughput range 0.5 to 5 kg/h, extruder suitable for filament production for additive manufacturing.

| Technical data | |

| Screw diameter | 11 mm |

| Specific torque | 6 Nm/shaft |

| Screw speed | up to 1000 min-1 |

| L/D-ratio | 40:1 |

| Material output | 0.5 to 5 kg/h |

| Number of solid doses | 2 (gravimetric) |

| Degassing/Venting | Atmospheric |

| Speed | 0.5 to 15 m/min |

| Coil inside diameter | 50 mm |

| Filament diameter | 1 to 3 mm |

| Max. coil width | 120 mm |

| Take-off height | 270 mm |