ENK - Energy-efficient and sustainable production of plastic components

| Year: | 2024 |

| Funding: | BMWK |

| Duration: | 01/2024 to 12/2026 |

The rise in prices for energy and raw materials has meant that energy savings and the efficient use of resources have gone from being a subordinate aspect to a key priority for operational improvements within entire branches of industry and are now an essential necessity. In addition to the fulfilment of legal requirements with regard to defined environmental targets, energy efficiency measures are more necessary than ever, especially in Germany as a production location and also against the background of international competitiveness.

This is precisely where the ENK research project - energy-efficient and sustainable production of plastic components - steps in. The ENK project is funded by the Federal Ministry of Economics and Climate Protection (BMWK) as part of the 7th Energy Research Programme of the Federal Government and is being carried out under the auspices of the Jülich Project Management Agency. The project consortium has set itself, as the main objective of the joint project, to reduce the use of electrical energy in the production of plastic components by at least 30%. In view of the critical debate on climate protection and rising energy costs, which particularly affect the production of plastic components, the project is at the centre of a forward-looking problem that directly affects over 2,900 companies and 320,000 employees in Germany.

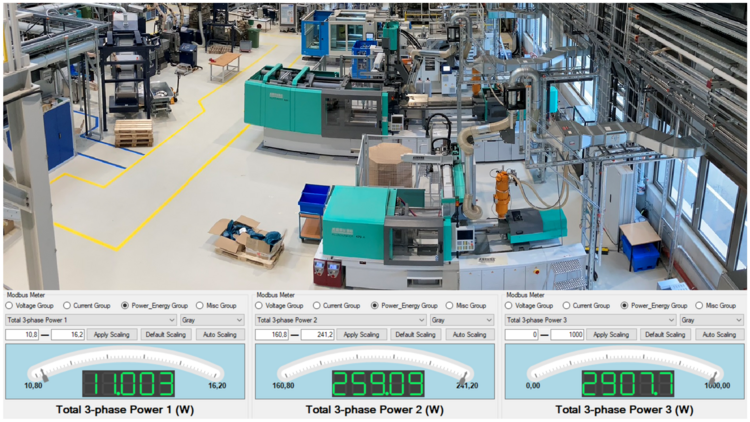

Over the course of the project, the project partners are working on the development and implementation of an AI system for monitoring and controlling plastics production processes. This will initially be implemented and trialled in the machinery of the IKK - Institute of Plastics and Circular Economy - and used to produce a demonstrator before being transferred to industrial manufacturing processes. The system is intended to enable more precise control and thus a significant reduction in energy consumption in plastics processing. In addition, a model for identifying and minimising inefficiencies and energy losses is being developed on the basis of the demonstrator, which integrates and combines energy, sustainability and value creation aspects and can then be transferred to industrial components.

Contact

M. Sc. Stefan Kerkenberg

kerkenberg@ikk.uni-hannover.de

+49 511 762 13436