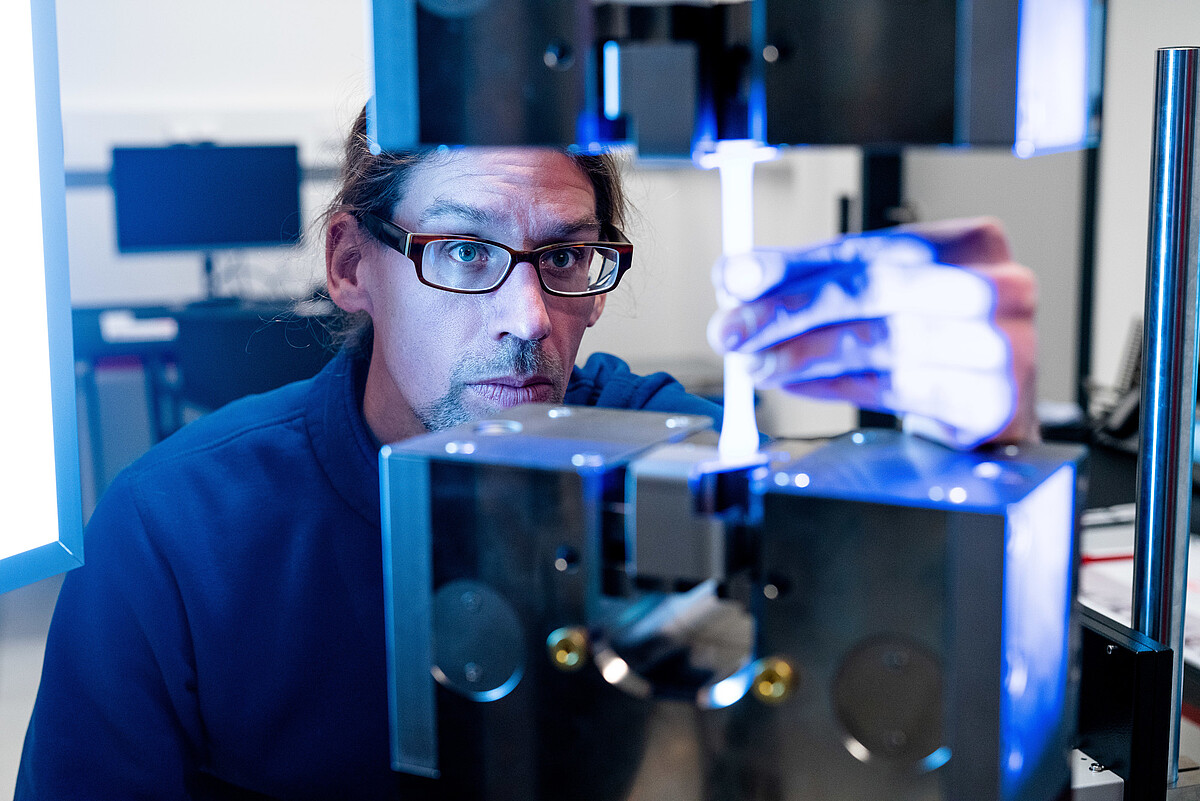

Material Testing

Core task of the Department of Material Testing is the comprehensive destructive and non-destructive characterisation of material and component samples to obtain knowledge about processing properties, application-specific material performance, failure behaviour and degradation behaviour. Testing is focused on plastics and fibre-reinforced plastics, but is not limited to these materials.

In addition to established methods, for example for the standard-compliant determination of mechanical characteristics, novel methods are also being developed.

©

IKK

©

IKK

The Department of Material Testing covers:

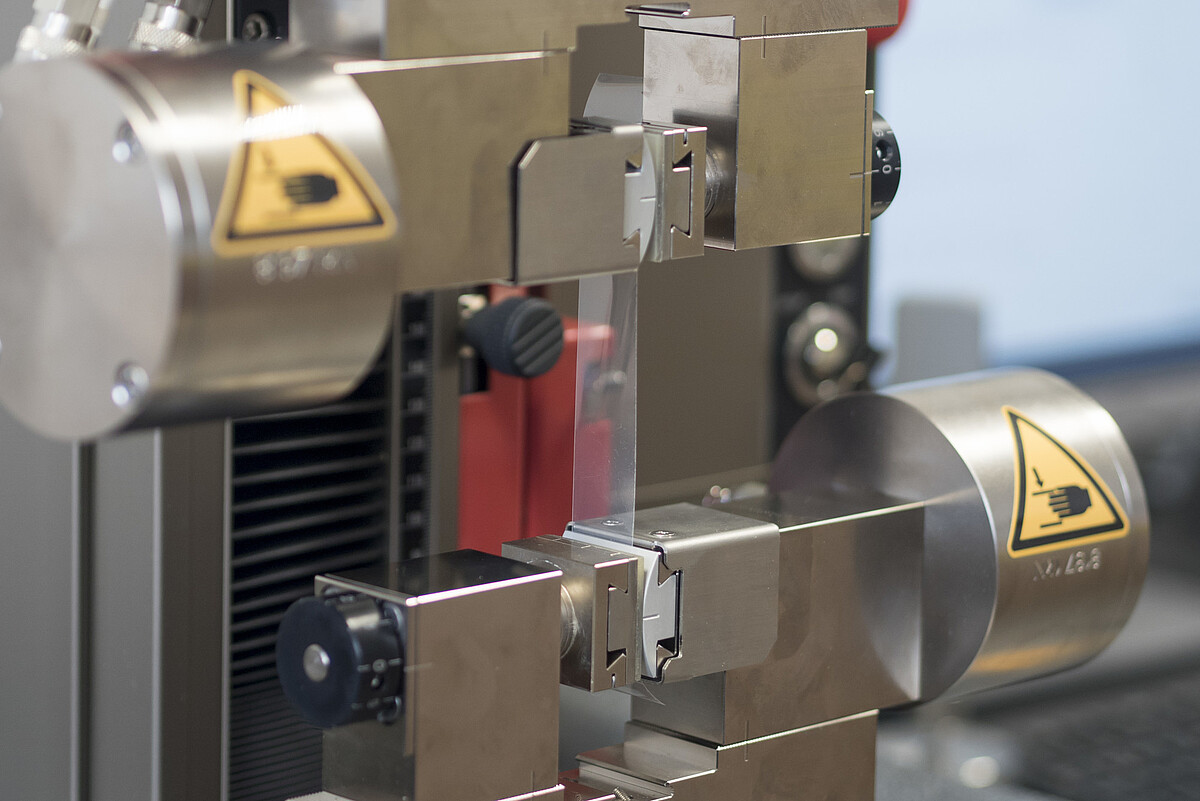

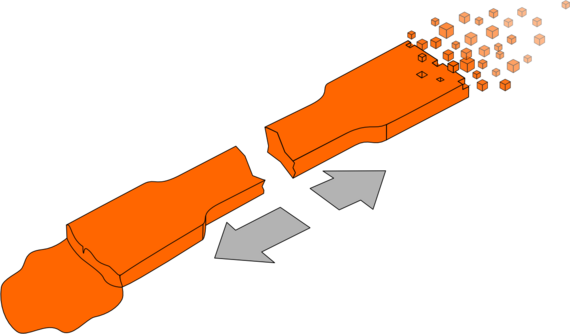

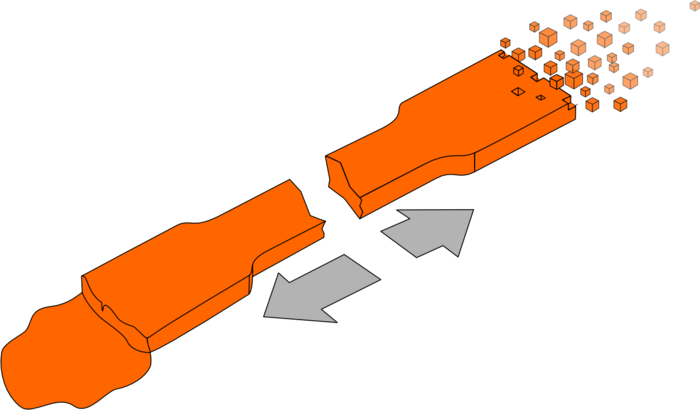

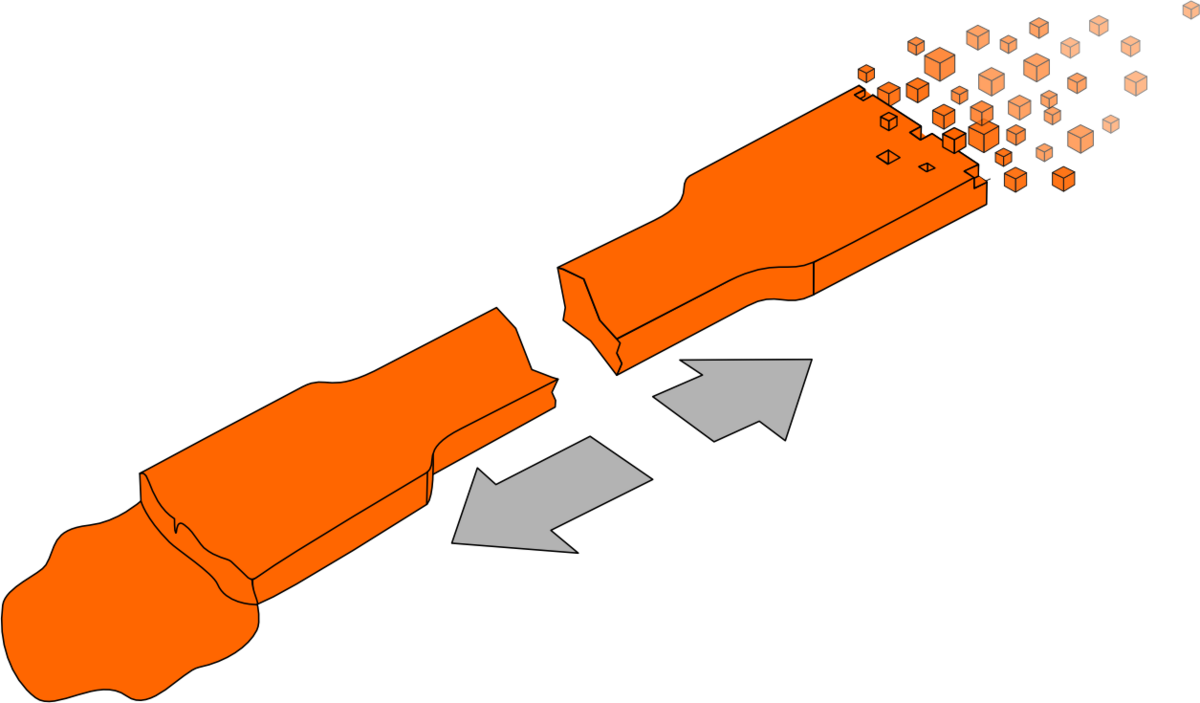

Mechanical Material Testing

In order to determine mechanical material characteristics, tensile, compression, bending and impact bending tests can be carried out with state-of-the-art testing machinery, both under standard climatic conditions and at controlled temperatures. This is supplemented by hardness tests and creep tests to investigate long-term creep behavior.

Thermal Analysis

Thermal analysis includes the determination of processing-relevant properties of plastic melts such as melt viscosity, pVT data or thermal conductivity. This allows relevant material parameters to be determined for carrying out injection molding simulations, for example. In order to investigate the thermal suitability of the materials under the conditions of the use phase, the heat deflection temperature can be determined.

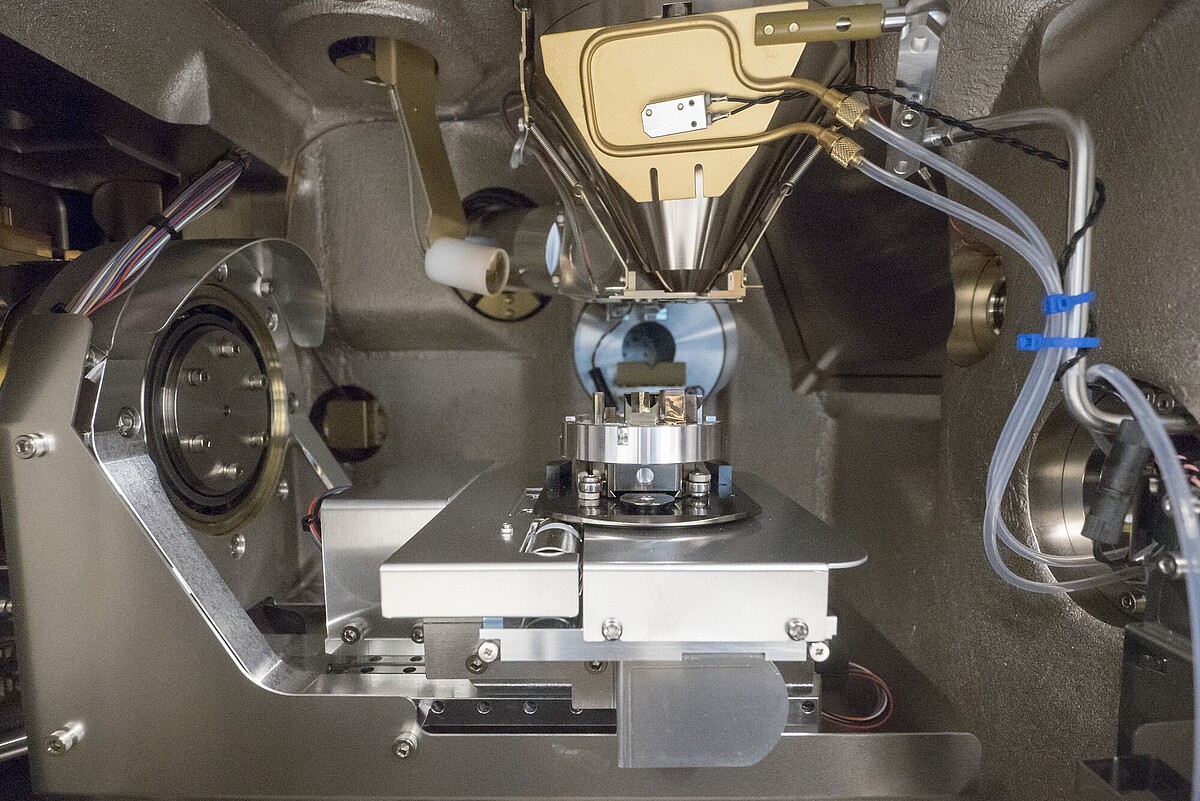

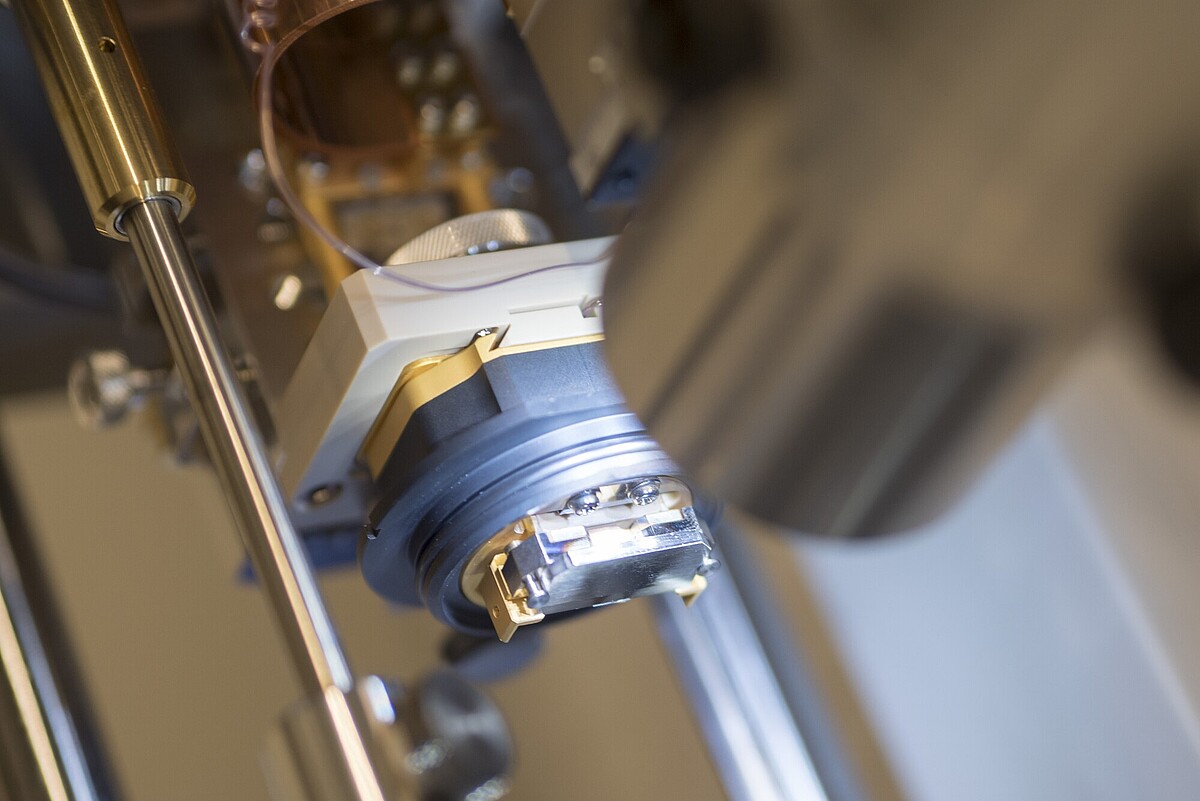

Imaging Analysis

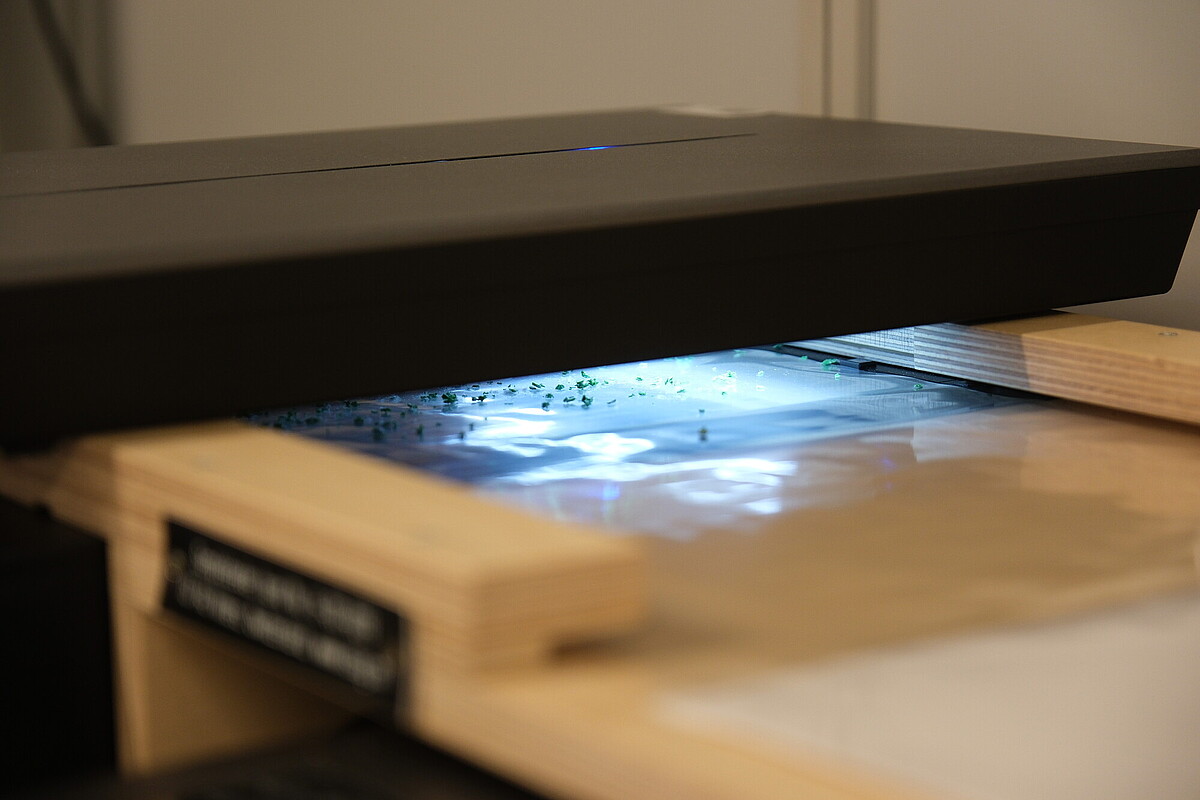

Using 3D digital microscopy and scanning electron microscopy (SEM), samples can be visualized on different scales down to a resolution in the single-digit nanometer range. Energy-dispersive X-ray spectroscopy can also be used in SEM investigations to determine element contents and distributions in samples with spatial resolution. Various methods such as cutting, microtomy, argon ion polishing or sputter coating are available for sample preparation. A particle and fiber measurement system enables the 2-dimensional measurement of the geometric properties of particles and fibers from a diameter of approx. 10 µm.

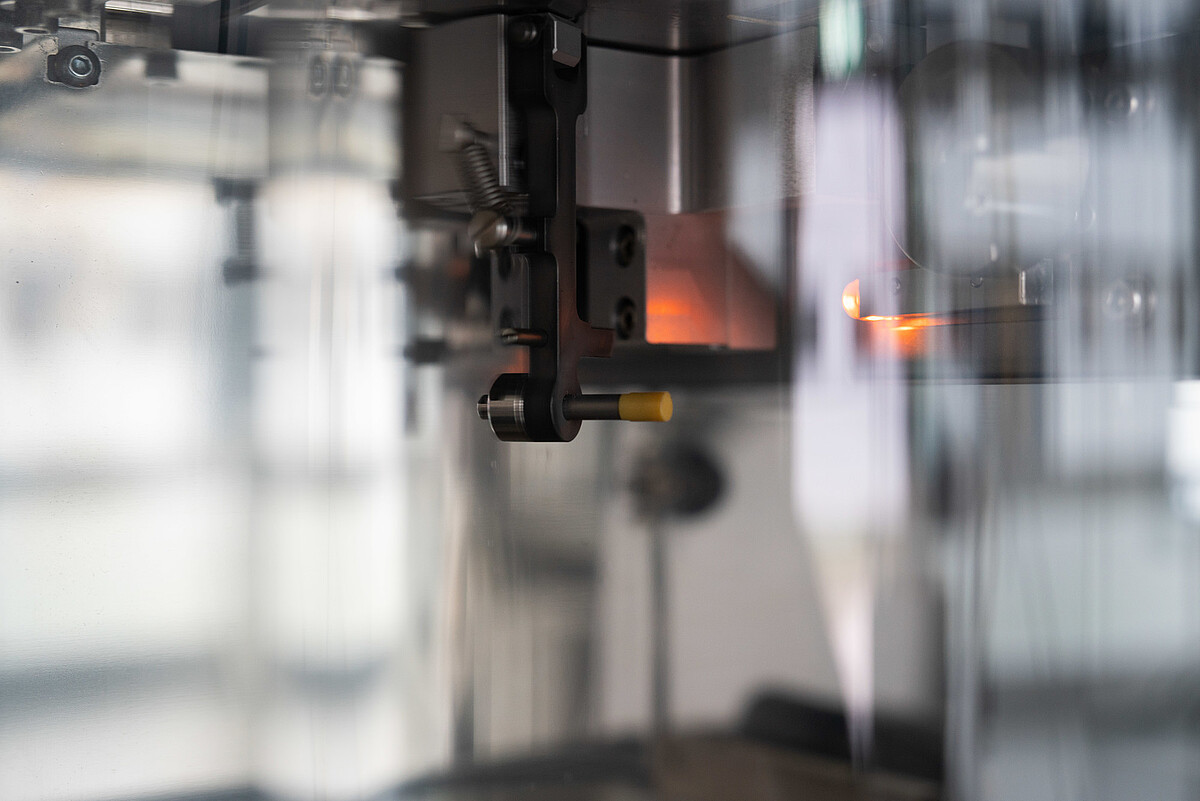

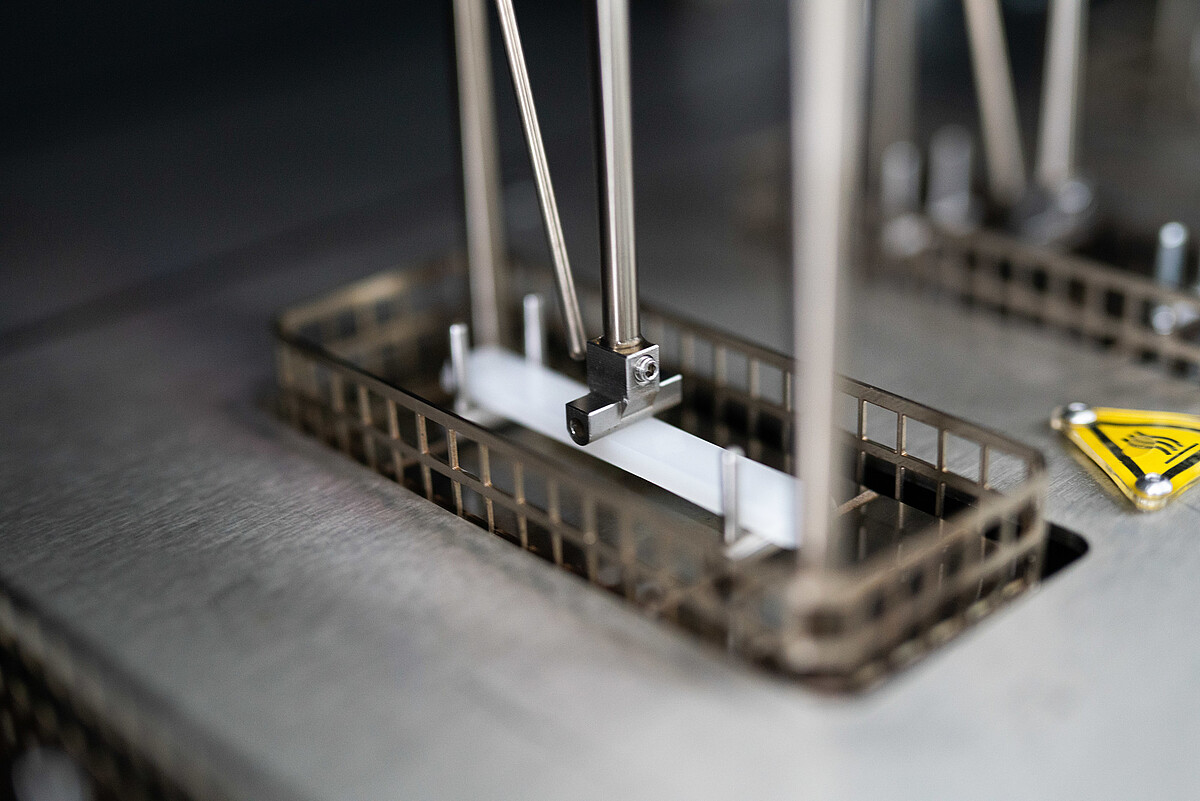

Environmental testing and degradation experiments

Testing facilities for accelerated weathering, such as a xenon test chamber and an environmental stress chamber, are available for investigating material behavior under environmental influences during the use phase. The behavior of plastics in the environment is investigated in a multi-scale test laboratory. Here, the biodegradability of plastics can be studied in laboratory tests and the influence of various abiotic parameters such as UV radiation or waves on degradation in micro- and mesocosm tests.

Contact the Department of Material Testing

© Christian Wyrwa

© Christian Wyrwa

© Christian Wyrwa

© Christian Wyrwa

30823 Garbsen